Introduction

- C19010 (CuNiSiP) is a high-quality alloy specifically designed to meet the stringent demands of the electronics industry. This alloy combines the high conductivity of copper, the strength and toughness of nickel, the heat resistance of silicon, and the corrosion resistance of phosphorus, resulting in a range of outstanding performance characteristics.

- The addition of nickel enhances the alloy’s strength and hardness, playing a crucial role in significantly improving its mechanical properties while maintaining good electrical conductivity.

- Silicon serves a dual purpose. First, it combines with nickel to form Ni2Si intermetallic compounds, which are the source of the alloy’s precipitation hardening capability. This process, commonly known as age hardening, allows the alloy to achieve high strength levels after heat treatment. Additionally, silicon enhances the alloy’s overall stability and corrosion resistance.

- High Strength, Excellent Electrical Conductivity, Outstanding Corrosion Resistance, Good Workability and Formability, Thermal Stability

Chemical Composition

- Ni: 0.8%~1.8%

- Si: 0.15%~0.35%

- Cu: Remainder

Alloy Standard

- ASTM: C19010——ASTM B422/ASTM B888

- DIN: CuNi1Si——CEN/TS 13388

- EN: CuNi1Si——CEN/TS 13388

- JIS: C1901

Physical Properties

- Density: 8.91 g/cm³

- Electrical conductivility: 53 IACS%(20°C)*(value for the lowest temper class)

- Modulus of elasticity: 127 GPa

- Coefficient of thermal expansion: 16.8 10-6/K

- Thermal conductivity: 255 W/(m*K)

Mechanical Properties

Application

Thanks to its unique combination of properties, the C19010 alloy is widely used in various industries that require high strength, good electrical conductivity, and corrosion resistance. Key areas of application include electronic and electrical components, the automotive industry, telecommunications equipment, aerospace, and defense.

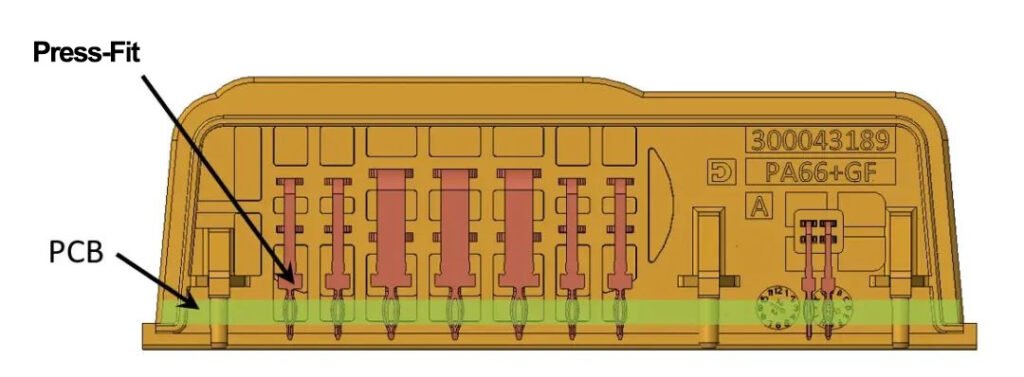

- Connectors and Press-Fit terminals / Press-fit pins: The alloy’s strength and conductivity are critical for ensuring stable connections in electrical connectors and terminals, especially in high-stress environments. These components are extensively used across a wide range of applications, from consumer electronics to industrial machinery.

- Electrical Springs and Switches: C19010’s ability to maintain its mechanical properties under stress and high temperatures makes it an ideal material for springs and switches in electrical relays. These components need to reliably open and close circuits under various conditions, and C19010’s properties ensure they can perform this task without failure.

- Automotive Sensors and Actuators: Modern vehicles rely on a variety of sensors and actuators to monitor and control various systems. C19010 alloy is used in the electrical connectors and terminals within these devices, ensuring they operate reliably under the harsh conditions typically found in automotive environments.

- Heat Sinks and Thermal Management Components: The alloy’s thermal stability and conductivity make it perfect for components that require efficient heat dissipation, such as heat sinks in electronic control units.

Stress Relaxation Resistance

- “Enjoy the freedom to design without compromise, thanks to 150°C stress relaxation resistance, outstanding conductivity, and superior plateability.”

- This version flows smoothly and emphasizes the benefits of the material in a balanced way. Let me know if there’s anything else you need!